Metal bars are one of the primary construction materials, providing strength and durability to structures. Available in various forms and functions, metal bars have many applications in construction projects.

Construction projects typically utilize five kinds of steel rods: warm rolled deformed bars, cold rolled deformed bars, TMT bars, twisted metal bars, and weld metal bars. Of these varieties, HYSD bars (Thermo-Mechanically Treat) offer greater tensile strength than mild steel bars. For more information about metal bars Click here.

Cold Rolled Steel Bars

Cold-rolled reinforcing bars are manufactured in specific lengths with close tolerances, featuring smooth surfaces free from scale. the oily build-up, or any undefined edges or corners, and being easier to weld than their hot-rolled counterparts.

Cold-rolled bars are manufactured without using heat during manufacturing, helping avoid internal stresses that might otherwise arise with hot-rolled products. This makes cold-rolled steel more dimensionally stable than its hot-rolled equivalent and. therefore, suitable for higher-stress applications; furthermore. they’re often more cost-effective and affordable, and easier to produce in large volumes.

Cold rolled steel bars differ significantly from their hot counterparts by starting as strips fed into a cold rolling mill and a cold working process that shapes them below their recrystallization temperatures, creating stronger yet more ductile bars with greater tensile strength.

Cold drawing, turning, grinding, and polishing processes enable bars to achieve an ideal yield point suitable for applications requiring precise dimensions and tolerances. such as gears and shafts, concrete accessories, hand tools, or vehicle axles.

Aluminum Bars for Construction Projects

Aluminum is one of the greenest construction materials thanks to its sustainable nature and versatility. Aluminum’s lower density than other metals like iron and copper allows construction professionals to reduce overall weight without impacting energy costs when building. Furthermore, producing it uses less energy than producing other primary metals. which means less material wasteful buildings. as well as lower cost of raw materials. Are created through production processes using less material than their counterparts.

To maximize the success of your aluminum project, it is vitally important that you select an alloy suitable for you. Aluminum comes in various alloys and shapes.

6061 Aluminum Bars for Construction Projects mes Aluminum square bar comprises one solid piece of aluminum extruded into its intended form and diameter for fabrication purposes. Often welded together into frames or structural components in buildings. square aluminum bars also play an integral part in aerospace and automotive components due to their strength and corrosion resistance.

Aluminum angle bars, formed by two legs meeting at 90-degree angles, can be an invaluable addition to various architectural and general construction applications. technical machine fabrication projects, and general fabrication projects. Aluminum angle bars come in an assortment of alloys, one popular variety is the 6060 series, which contains magnesium-silicon alloys that provide superior weldability with cold-forming practices and standard anodizing practices.

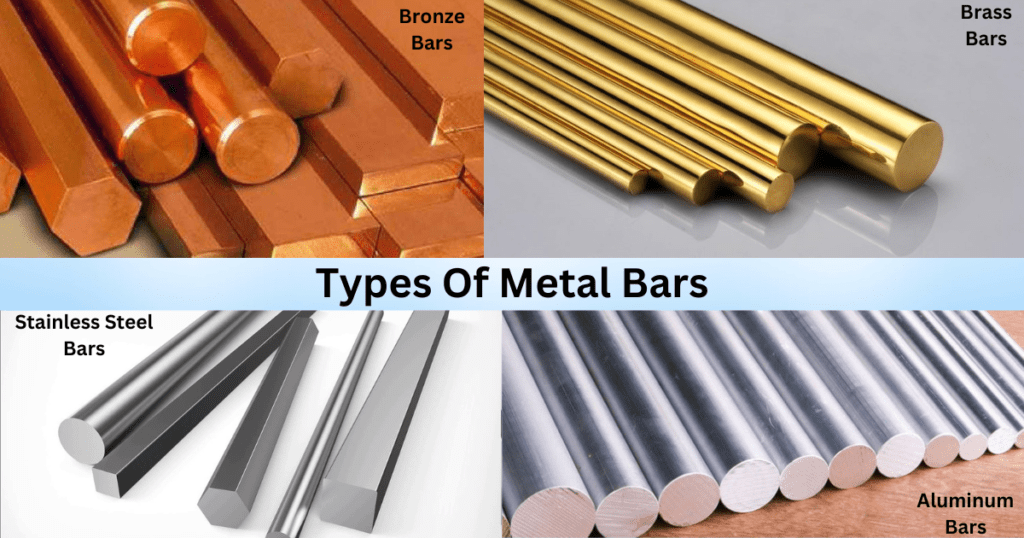

Brass Bars for Construction Projects

TMT bars are known for their durability and strength, which help ensure longevity for structures. Furthermore. These TMT bars exhibit highly corrosion-resistant and fire safety properties, which help mitigate risks related to structural collapse during fire incidents.

Manufacturer of brass angles, bars, coils, flat plates, and rectangles available in stock sizes and custom shapes. Shearing, heat treating, aging, and annealing services are provided. Serving aerospace, automotive, defense, and construction industries.

Bronze Bars for Construction Projects

Bronze bars are used in switchboards and distribution boards to efficiently branch current from the breaker’s primary-side circuit breaker, using holes drilled in them for attaching copper wires.

Brass, bronze, and copper are metal alloys composed of various amounts of tin, zinc, aluminum, and manganese atoms that exhibit different properties that make each metal suitable for specific construction projects.

Conclusion

The use of metal bars and rods in construction projects is essential due to their strength, durability, and versatility. Different metal bars and rods are available for various applications, including reinforcing concrete structures, creating load-bearing columns and beams, and providing support for buildings and other structures. Steel remains the most commonly used material due to its high tensile strength and ability to withstand heavy loads. By selecting the right type of metal bar or rod for a construction project, builders can ensure the safety and longevity of the structure.